Can Seam Inspection Equipment by

Longueville, Pound Lane, Smeeth, Ashford, Kent. TN25 6RJ. England

Tel: +44 (0)1303 813200 Mobile 07776 251493 E-mail: stevegoble@arundle-optical-instruments.com

Can Seam Inspection Equipment by

Longueville, Pound Lane, Smeeth, Ashford, Kent. TN25 6RJ. England

Tel: +44 (0)1303 813200 Mobile 07776 251493 E-mail: stevegoble@arundle-optical-instruments.com

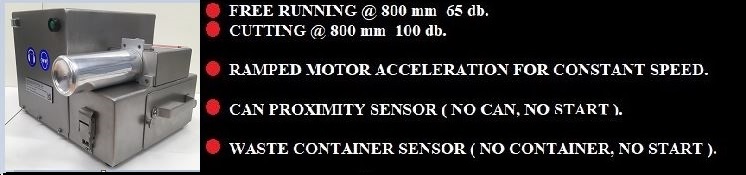

Compact Beverage Can Seam Sectioning Saw.

The Compact beverage can sectioning saw has been designed to maximise work top bench space.

The beverage can saw has a unique cutting design to achieve

Longer blade life resulting in precise cutting repetition

Reduce cutting movement, saving time

Cost effective blades (H.S.S. M35 100 x 22 x 0.5 x 300 Teeth)

Quick change seam fixture

Blade support to eliminate lateral movement of blades

The linear bearing cutting table has a seam fixture, this has an internal chuck angle to locate the food can firmly and ensures that the cans are consistently cut through the centre line of the can.

Ramped motor acceleration for immediate maximum cutting torque.

Saftey first.

Both hands have to be employed while cutting

Removable power cord (230 Volts)

Illuminated mains Off / On switch

Spring return blade guard

Ultra low voltage control circuits

Push button (Automatic off return)

Can proximity sensor (No Can No Start)

Waste cutting material container sensor (No container, No start)

Available in 110volt version.

Supplied

with the following.

1 Off seam fixture

2 Off spare saw blades (H.S.S. M35 100 x 22 x 0.5 x 300 Teeth)

1

Off pair of flat nose pliers

2 Off blade change 24AF spanners

T-bar M5 Allen socket wrench

Features.

Easy clean stainless steel cabinet

Dimension: Length 300mm Width 230mm Height 210mm

Weight 11Kg (24.2lbs)

Free running at 800mm 65db cutting at 800mm 100db (1to2 Seconds)