Can Seam Inspection Equipment by

Longueville, Pound Lane, Smeeth, Ashford, Kent. TN25 6RJ. England

Tel: +44 (0)1303 813200 Mobile 07776 251493 E-mail: stevegoble@arundle-optical-instruments.com

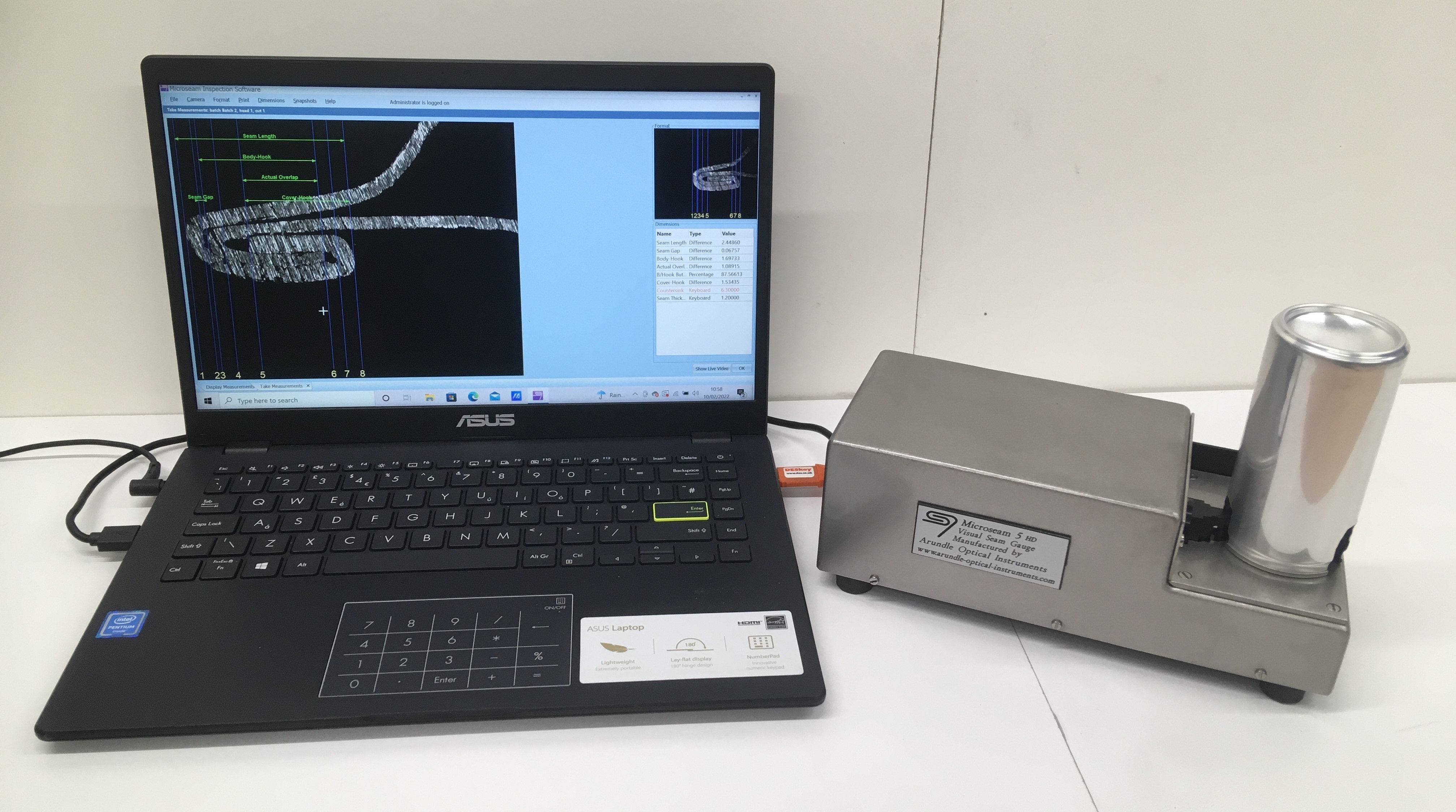

Beverage can Microseam 5 Standard High definition (HD) can seam inspection system with New feature. Structured Query Language database file.

Beverage can Microseam 5 standard is Arundle Optical Instruments next evolution in the Microseam range provides an effective low cost alternative to an optical projection system, with the added advantages of a high quality digital image and the retention of raw data .

Viewing head is a compact, easy clean stainless steel clad unit utilizing a USB 2 High definition digital camera with integrated Deskey for added security.

The camera takes an optically magnified snapshot, measuring lines are then positioned onto this image to be measured.

User friendly software has been developed to be Windows XP, Vista,Windows 7, Windows 8 or 8.1 and Windows 10 compliant with networking capability, requires minimal operator training with the software doing all the calculations.

Leading edge locating adaptive algorithm.

Virtual control panel allows the operator to adjust the camera for optimal image quality.

Bitmap graphical display with measuring points indicated to assist familiarization of new operatives.

New feature. Edit in the program configuration dialogue box allows datafile storage to be selected between "DAT" files or "SQlite".

SQLite

database for immediate data acquisition by third party

applications using an ODBC database connection for virtual real

time availability of the measured data.

Data files are configured using a simple set up, allowing difference, optional gauge measurements, key board and formula inputs.

Formula's for tear down procedure included in set up, so that parallel inspection can take place on data base.

Microseam 5 Standard

allows you to......

Define

the seam dimensions you require to measure.

Define

the measurements required to achieve those dimensions.

Define

the calculations to be applied to achieve those measurements.

Input

from optional digital gauges with RS

232 output

.

Microseam 5 standard

has...............

Measurements

displayed in table form.

3

levels of password security.

Day

/ date raw data retrieval.

Can

batch coding.

On

screen seam image display with user defined measuring points for

operative familiarization.

5

micron accuracy.

X2

digital zoom

for precise placement of measuring lines.

Auto sequencing of can

and cut.

Automatic data calculation with fine band tolerances.

Data file copy and editing facility.

Standard deviation and

average at the end of each measuring cycle.

Large screen measuring image for improved accuracy.

Measuring screen allows image dimensions to be displayed with text description or numeric values.

Microseam 5 Professional is supplied as viewing head, software, Deskey, calibration piece and printed user manual, with the customer supplying their own computer,(specification required below).

Desk top or Lap top.

CPU: Intel Pentium 4, 1.5 GHz or faster.

O/S: Windows XP, Vista or Windows 7, 8 , 8.1, 10 and Windows 11.

RAM: Minimum 256 MB more recommended.

Hard Drive: at least 150 MB of available disk space.

VGA card: 16 bit or above.

USB: 2 off avalible ports minimum (USB 2.0 recommended).

CD-ROM drive.

AlternativelyMicroseam 5 standard may be supplied as a complete pre calibrated factory unit with single or multiple data files set up to customers specifications.

All that is required is

to connect leads as indicated,turn on, click on to Microseam 5 icon

and GO.

Supplied with

Calibration piece

and printed user manual.

Upgrade to Microseam 5 Professional by the purchase of software licence code.